As metal 3D printing becomes the buzzword in the additive manufacturing industry, many argue it can...

Metal 3D Printing is an ever-evolving technology with the potential to take the manufacturing industry to new heights, thanks to its capability to produce intricate and optimized designs.

This production method has already improved productivity in several industries, including oil & gas, steel production and mining. One of the most recent and exciting applications of metal 3D printing is the production of closed impellers, but the complexity of these parts makes it challenging to produce with LPBF due to the amount of support structures needed which ultimately complicates printing and post-processing.

In collaboration with EOS, TheSteelPrinters have developed an LPBF process for producing closed impellers that minimizes the use of support structures. As a result, these parts can be produced faster and more cost-efficiently, since less material and post-processing time is required.

TECHNICAL CHALLENGES

Metal 3D printing a closed impeller using LPBF (Laser Powder Bed Fusion) technology presents several challenges. Closed impellers have complex geometries with internal channels and low-angle overhang features, that necessitate the use of internal support structures.

Internal support structures add to the material costs and printing time, and they can be challenging to remove with post-process machining, often resulting in surface finish defects. Additionally, the requirement for post-process machining leads to increased costs and longer manufacturing lead times.

To overcome these challenges, a "support-free" printing strategy is therefore preferred. Achieving this strategy requires a comprehensive understanding of the LPBF process and printing material properties, and it is essential to develop bespoke printing parameters.

PROCESS DEVELOPMENT

The R&D department of TheSteelPrinters conducted multiple experiments aimed at developing a "support-free" 3D printing strategy for closed impellers. These experiments involved analysing various printing parameters, such as laser power, laser speed, hatching distance, and downskin thickness, to obtain different downskin energy per volume (J/mm3) values.

Through these experiments, the team developed a new approach called "High Energy Down Skin" (HEDS), which modifies the "Downskin parameters" to create a stronger welded zone that can withstand recoating forces. This approach has significantly improved the manufacturability of overhangs, allowing the production of closed impellers without the use of internal support structures.

An overview of the HEDS development tests and their results are detailed below:

In Experiment 1, we studied five different parameter configurations, each with varying downskin energy values, while considering process variables such as gas flow direction and recoating direction. Tests were conducted on test pieces with a 25mm overhang using the EOS M290 system. As a result, three out of the five test pieces were printed successfully.

Experiment 2 involved transferring the testing to a high productivity system, using test pieces with the same overhang length of 25mm, but with the process conditions of the EOS M400-4 system. We studied a total of seven printing parameters, comprising of three from the previous experiment and four new parameters. However, the outcome revealed that only three of the test pieces were printed successfully using the M400-4 process conditions.

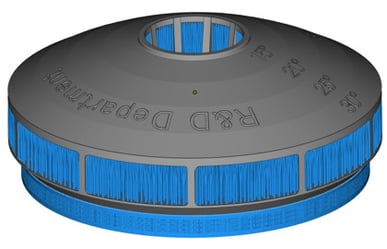

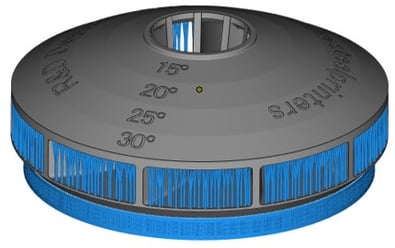

In Experiment 3, we once again studied a total of seven printing parameters, consisting of three from experiment 2 and four new parameters, using an EOS M400-4 and test pieces with overhang lengths of 35mm. The testing phase culminated in two out of the seven test pieces being printed successfully, thus validating two printing parameter configurations.

%20(1)-2.png)

Figure 5: Testing part with overhang of 35mm.

%20(1)-2.png)

Figure 5: Testing part with overhang of 35mm.

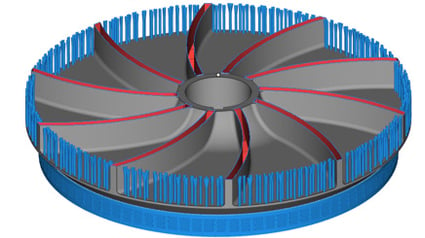

Lastly, using the results from Experiment 3, Experiment 4 was conducted, where the two validated printing parameter configurations were tested by producing a closed impeller with a diameter of 15 cm and with multiple overhang angles. Both parameter configurations successfully produced impellers without overhang failures, albeit with slight differences in surface resolution.

CONCLUSIONS

The successful development of the HEDS approach marks a significant milestone in the production of closed impellers and parts featuring low-angle overhangs.

By eliminating the necessity of internal support structures, closed impellers can be manufactured with superior dimensional accuracy, reduced lead time, and cost-effectiveness.

The use of the HEDS approach can reduce unit prices by as much as 30% for the production of a single closed impeller and up to 45% for bulk orders, thereby rendering additive manufacturing a more financially viable solution for the production of pump components and spare parts.

IMPELLER PRINTED USING STANDARD PARAMETERS.

.jpg?width=454&height=213&name=Imagen6%20(1).jpg)

- Printing time without laser overlapping: 56H.

- Total volume: 335 cm3.

- Support volume: 196 cm3 (41% of total volume).

IMPELLER PRINTED USING HEDS PARAMETERS.

- Printing time without laser overlapping: 42H.

- Total volume: 237cm3.

- Support volume: 41 cm3 (17% total volume).

ARE YOU READY TO START INVESTING IN ADDITIVE MANUFACTURING?

Then why not take the first step and start your additive manufacturing journey? To help you along the way, we’ve created this helpful and insightful guide with all the information you need.

We’ve covered the opportunity for added value savings, how design and metal 3D printing go hand in hand, and a practical example to follow. Get your copy now by clicking the link below.